In 2014, the Legislature passed new laws intended to improve state oversight of hydraulic fracturing, or "fracking." In this web post, we provide a progress report on the implementation of these new laws and a high-level overview of how hydraulic fracturing is used to stimulate oil and natural gas production.

LAO Contact

December 1, 2016

Hydraulic Fracturing: How It Works and Recent State Oversight Actions

Over the past decade, the practice of stimulating oil and natural gas production through the use of hydraulic fracturing, or “fracking,” has come under increasing scrutiny, particularly over concerns about the potential for contamination of groundwater aquifers and other environmental and health-related issues. In response to these concerns, the Legislature passed new laws in 2014 intended to improve state oversight of hydraulic fracturing in California. Specifically, the laws (1) more closely regulate hydraulic fracturing, (2) require drillers to be more transparent about their operations, and (3) require studies to be undertaken to better inform future policy decisions. In this web post, we summarize the recent legislation and provide an update on its implementation by the Department of Conservation (DOC) and other state agencies. We start by providing a high-level overview of how oil and natural gas reservoirs are formed and why hydraulic fracturing is sometimes used to stimulate wells.

Overview of Oil and Gas Drilling in California

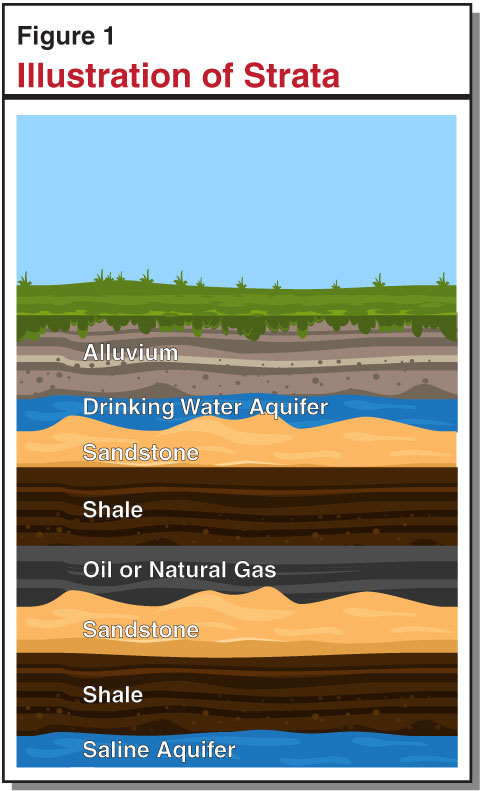

Oil and Natural Gas Reservoirs Are Formed Over Millennia. Oil and natural gas reservoirs are found in the earth’s crust, which is typically about 18 to 30 miles thick under the continents and 3 to 5 miles thick under the oceans. Millions of years ago, organic matter—mostly from dead plants and marine microorganisms—accumulated at the bottom of the sea. This organic matter was buried by sand, silt, and other sediments. Over time, natural forces such as heat and pressure compacted the layers of sediments into layers of rocks such as sandstone and shale. These natural forces also broke down the organic matter, converting it into oil and natural gas. Figure 1 illustrates how a cross-section of the earth’s crust can look after this process has taken place.

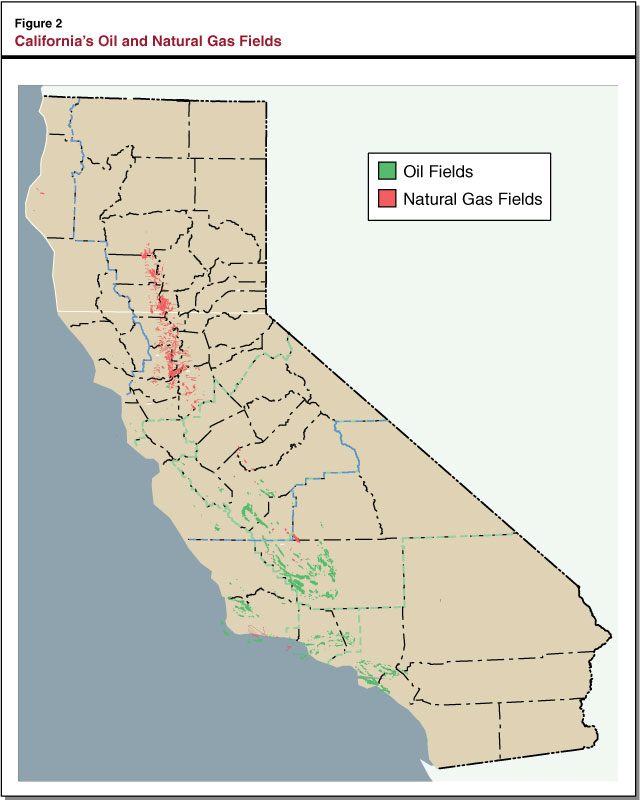

California’s Oil and Natural Gas Fields Are Concentrated in Certain Areas. As shown in Figure 2, California’s oil fields are concentrated mainly in the southern coastal regions and in the San Joaquin Valley. The state’s natural gas fields are mostly located in the northern part of the central valley. Currently, there are roughly 83,500 wells in California producing oil or natural gas.

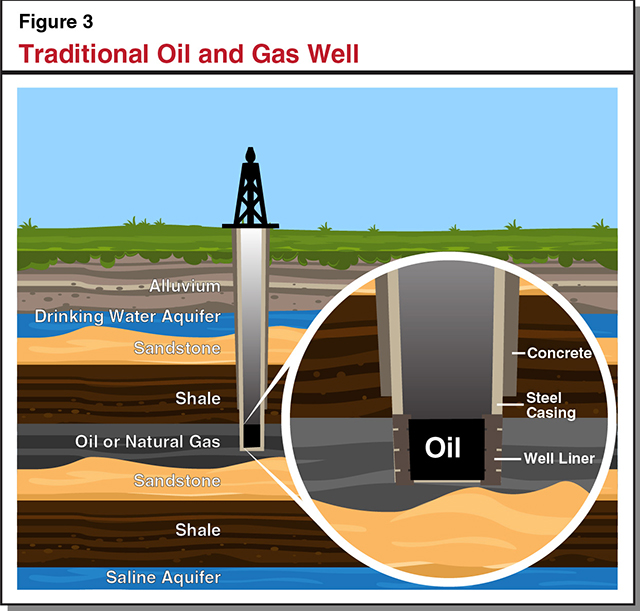

Description of How Oil and Natural Gas Wells Traditionally Are Drilled. In some places, relatively impermeable sedimentary rock such as shale forms a cap over an oil or natural gas reservoir that prevents the oil or natural gas from seeping upwards towards the surface. In this scenario, it is often possible to drill a well through the cap rock to reach the oil reservoir. As discussed more below, in other places, oil and natural gas reservoirs are trapped within rock formations too impermeable to allow the oil or gas to flow to the well. In these cases, well stimulation techniques (such as hydraulic fracturing) may be necessary to free the oil or natural gas up for production.

As shown in Figure 3, drilling rigs drill down from the earth’s surface through underlying strata of alluvium, aquifers, and rock until they reach oil or gas reservoirs. Wells can vary significantly in depth from relatively shallow wells (a few hundred feet deep or less) to relatively deep wells (10,000 feet deep or more). Once a drilling operation has reached an oil or natural gas reservoir, a pipe (known as a casing) is usually placed in the wellbore from the surface down to the oil or natural gas reservoir. This casing is usually secured by pumping concrete between it and the well wall in order to prevent oil and natural gas from migrating up out from the wellbore and contaminating overlying aquifers and strata. Once the concrete has set, a perforated casing (called a liner) is placed at the bottom of the wellbore in the oil or natural gas reservoir to allow the oil or natural gas to enter the well and be pumped up to the surface.

Three Well Stimulation Techniques Are Used. Based upon data from DOC, in both 2014 and 2015 slightly less than 1 percent of the roughly 83,500 producing oil and natural gas wells in California were stimulated. However, we note that a single well can be stimulated more than once. Of the wells stimulated in California in 2014 and 2015, 98.2 percent were stimulated using hydraulic fracturing, 1.7 percent were stimulated using matrix acidizing, and 0.1 percent were stimulated using acid fracturing. These well stimulation techniques are defined as follows:

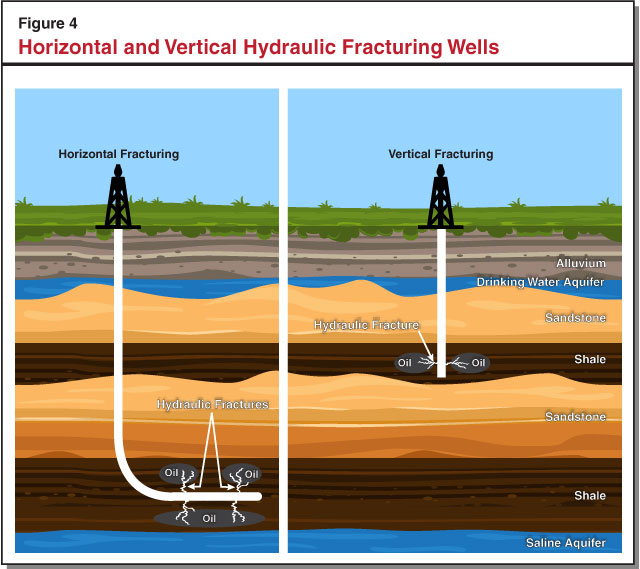

Hydraulic Fracturing. Hydraulic fracturing is accomplished by pumping well stimulation treatment fluids (mainly water, chemical additives, and sand or ceramic man-made materials known as proppants) down the well under high pressure and out through holes in the well casing to fracture the surrounding rock formation. After the fracturing is completed, the water and chemicals, known as flowback fluid, is recovered from the well, while the proppants remain to prevent the fractures from closing. The oil or natural gas flow through the porous fractures into the well and are pumped to the surface. The flowback fluid from hydraulic fracturing operations must be properly disposed of by injecting it into the ground in injection wells. Figure 4 illustrates both vertical fracturing, and horizontal fracturing. The horizontal well also illustrates a two-stage fracturing job in which the rock surrounding the well is fractured in two different places along the wellbore.

Matrix Acidizing. Matrix acidizing does not fracture the rock, instead, acid pumped into a well at relatively low pressure dissolves the rock and makes it more permeable.

Acid Fracturing. Unlike hydraulic fracturing, which uses mainly water and chemical additives, acid fracturing is the high-pressure injection of mainly acidic fluid into a well to fracture the rock and etch the walls of the fractures.

Both the California DOC and the U.S. Environmental Protection Agency provide more information on well stimulation techniques.

Well Stimulation in California. In California, about 86 percent of the well stimulations undertaken in 2014 and 2015 were on oil and natural gas production wells. The remainder of stimulations were on injection wells used to dispose of produced water (see below) and flowback fluid.

Approximately 85 percent of all hydraulic fracturing operations take place in relatively shallow wells less than 2,500 feet deep (as compared to other parts of the country where hydraulic fracturing operations often take place in wells several thousand feet deep). In some places, aquifers used for drinking water and irrigation exist near shallow hydraulic fracturing operations, and this presents a risk that hydraulic fractures could connect to the aquifers and contaminate them.

Traditional Drilling and Hydraulic Fracturing Can Produce Wastewater. Oil and natural gas drilling operations in California—including using both traditional and stimulation techniques—can yield significant amounts of water as a by-product. For example, some oil and natural gas wells produce more water—known as “produced” water or “wastewater”—than oil and natural gas. Produced water has to be separated out from the oil and natural gas and disposed of in accordance with state regulations. In some cases, produced water can be reused for oil and natural gas production. Depending on the water’s quality, produced water can also be used for other purposes (such as irrigation). In some cases produced water is disposed of in unlined sumps or ponds.

Legislature Raises Concerns About Hydraulic Fracturing

In Chapter 313 of 2014 (SB 4, Pavley), the Legislature found that insufficient information is available to fully assess the potential effects of hydraulic fracturing and other well stimulation treatments in California, including environmental, occupational, and public health hazards and risks. The Legislature enacted several requirements designed to provide greater transparency and accountability to the public regarding well stimulation treatments; emissions to the environment; and the handling, processing, and disposal of well stimulation wastes.

In addition, Chapter 561 of 2014 (SB 1281, Pavley) requires reporting of specific data regarding the source, volume, and storage and disposal status of water produced during oil and natural gas drilling operations—including during hydraulic fracturing operations—in order to provide regulators and policy makers with key information to evaluate how industry practices affect groundwater.

Update on Implementation of Recent Legislation

Below, we provide an update on the implementation of the key provisions of SB 4 and SB 1281.

Implementation Status of SB 4. Senate Bill 4 imposes several requirements on state agencies and the oil and natural gas industry. Under SB 4, monies from the Oil, Gas, and Geothermal Administrative Fund (OGGAF)—which is funded by an annual charge upon each person operating or owning an interest in an oil or gas well—may be used by DOC, the State Water Resources Control Board (SWRCB), and regional water quality control boards to carry out the requirements of the bill. The following actions have been taken to date to implement the bill’s main requirements:

Well Stimulation Regulations Promulgated. Senate Bill 4 requires the DOC to adopt well stimulation regulations in consultation with the Department of Toxic Substances Control, the California Air Resources Board, the SWRCB, the Department of Resources Recycling and Recovery, local air districts, and regional water quality boards in areas where well stimulation treatments occur. These regulations are required to include provisions related to the construction of wells and well casings and the composition of well stimulation fluids. The final regulations have been promulgated and took effect on July, 1, 2015. The department notes that it is likely that it will develop additional minor “clean-up” type regulations in the future.

New Operator Permitting Process Developed. Senate Bill 4 requires operators to obtain a permit from DOC prior to performing a new well stimulation or repeating a well stimulation treatment. The department’s newly developed permit application requires operators to provide certain information including: (1) well location, type, and depth; (2) anticipated water source, volume, and disposal method; (3) a spill contingency plan covering well stimulation fluids; (4) anticipated chemicals used in the well stimulation fluids; (5) the fracture design; and (6) California Environmental Quality Act review. The department is now using the new permitting process.

Random Periodic Inspections Performed. Senate Bill 4 requires random periodic spot check inspections to ensure that the information provided on well stimulation treatments is accurately reported. The department reports it is performing these spot check inspections.

Well Stimulation Fluid Composition Information Available. Senate Bill 4 requires full disclosure to DOC of the composition, storage, and use of well stimulation fluids. The bill provides a special process for those suppliers claiming trade secret protection. The bill further requires operators to post information on well stimulation fluids on an internet site accessible to the public. The DOC maintains a searchable database of this information, which is available here.

First Annual Report on Well Stimulation Provided. Beginning January 1, 2016, SB 4 requires DOC to annually provide a comprehensive report on well stimulation in the exploration and production of oil and natural gas. The first report was completed at the end of 2015. According to the report, during the interim period when emergency regulations were in effect prior to the adoption of permanent regulations (January 1, 2014 through June 30, 2015) 2,127 well stimulation permits were approved for 15 operators. About 95 percent of these permits were for hydraulic fracturing. With a few exceptions, well stimulation treatments were limited to Kern, Kings, and Ventura counties in relatively well-established oil fields.

Initial Independent Study Completed. Senate Bill 4 requires the California Natural Resources Agency to contract for an independent scientific study on well stimulation treatments. The study was completed by the California Council on Science and Technology (CCST) and was released in July 2015. According to the study, some of the direct and indirect impacts of hydraulic fracturing are not yet fully understood. The study makes several recommendations—including for further research related to (1) the possible relationship between wastewater injection and earthquakes in California, (2) opportunities for water conservation and reuse in the oil and natural gas industry, and (3) chemicals used in oil and natural gas drilling operations and their effect on the environment and public health. As part of the 2016‑17 budget, the Legislature provided a total of $5.5 million from OGGAF over two years to contract for scientific services and to conduct additional scientific studies as recommended by the CCST report.

SWRCB Groundwater Monitoring Criteria Developed. Senate Bill 4 requires SWRCB to develop model groundwater monitoring criteria to be implemented either on a well-by-well basis for a well subject to stimulation treatment, or on a regional scale. The criteria were developed and are being implemented.

Implementation Status of SB 1281. Senate Bill 1281 includes two main requirements. First, the law requires DOC to annually provide SWRCB and California regional water quality control boards with an inventory of all unlined oil and gas field ponds and sumps. The department has submitted the inventory to SWRCB. According to the inventory, as of July 30, 2016, the combined total of active and inactive ponds under the jurisdiction of the Central Coast, Los Angeles, and Central Valley regional water quality control boards totaled 1,061. (The bulk of the ponds and sumps fall under the jurisdiction of these three regional water quality control boards.)

Second, SB 1281 requires well owners to report specified water-related information monthly to DOC. Required information includes (1) the amount of oil, natural gas, and water produced from each oil and natural gas well; (2) the source, volume, storage, and disposal status of all water used in or generated by oil and gas field activities; and (3) the ultimate use, disposal method, or method of recycling or reuse. The department has developed a standard format for operators to report this information and quarterly reports are available here. According to DOC, operators by and large have been reporting this information, but there are several operators who are failing to report their water data. As of October 2016, DOC estimates it was receiving approximately 90 percent of the data on produced and injected water. Notices of violations have been sent to those operators who have failed to submit, and DOC is putting together recommendations for civil penalties.